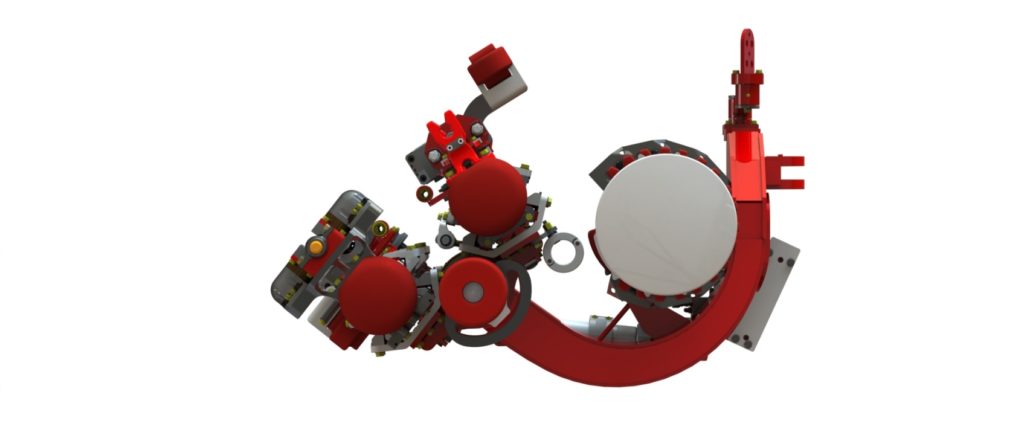

Rock Support Bolter Systems

Download/View Technical Specs Here (pdf-98kb)

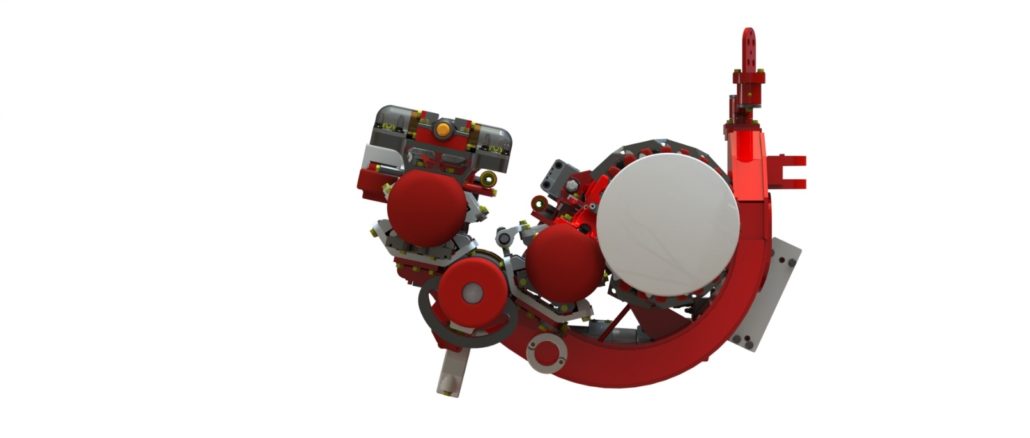

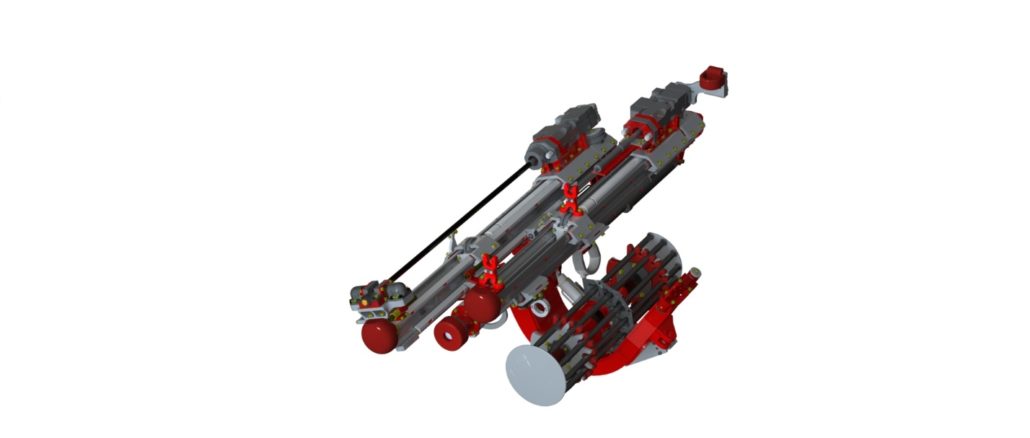

Timberock International designs, manufactures, and supplies its own complete OEM Bolter systems for underground rock support Bolters. Our bolters include many advanced features which increase production efficiency, and operator ease. An adjustable indexing system allows the operator to switch between drilling and bolting functions, while maintaining bolt alignment with drilled hole. The hydraulically operated bolt holding/ loading carousel makes for a more efficient bolting cycle. The Independent feeds allow the operator to maneuver the bolter with ease, into difficult situations. Our patented flexible bolt centralizer is a simple and cost-effective design, it is made from a single casted part, with shape-memory material properties which allows the centralizer to flex out of the way of the bolt driver.

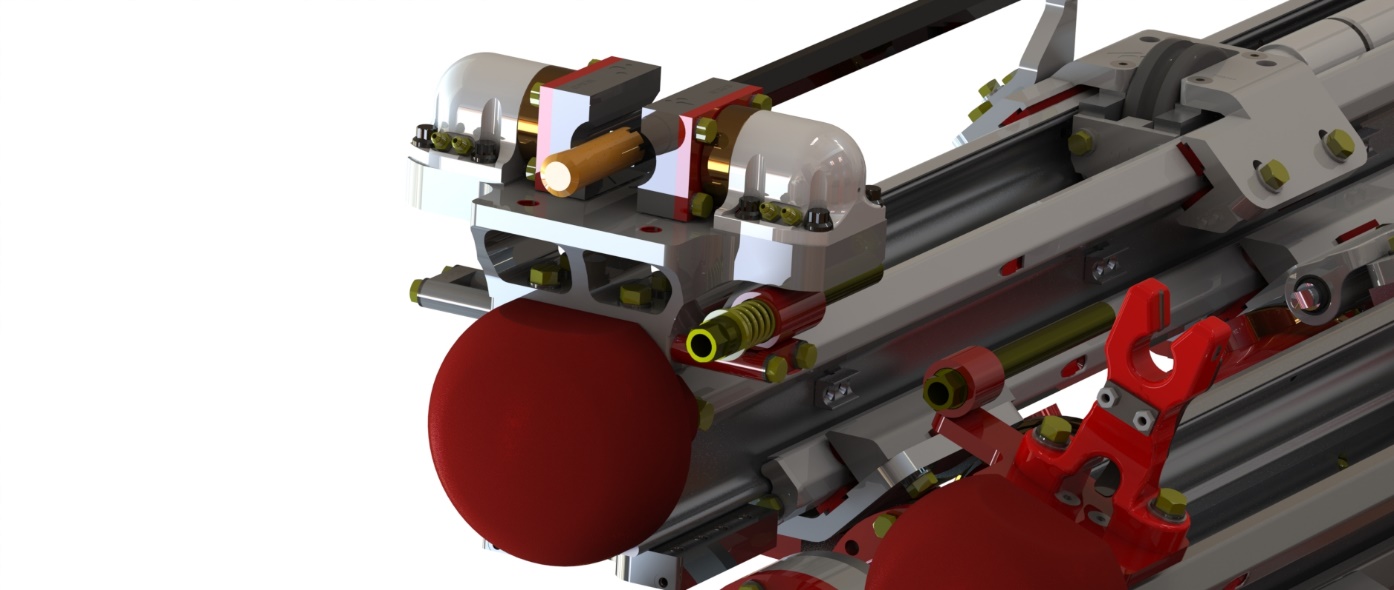

Hydraulic Centralizer:

Hydraulic Centralizer Option allowing for longer drill depth or drill steel extensions. Centralizer bushings are designed to both centralize the drill steel, and clamp onto the coupler.

Index System:

The indexing system allows for convenient and precise line-up of rock bolts with drilled holes.

Flexible Bolt Centralizer:

Our patented flexible bolt centralizer is a simple and cost-effective design. It is made from a single casted part, with shape-memory material properties which allows the centralizer to flex out of the way of the bolt driver.

Independent Feeds:

Our independent feeds help operators get into narrow and awkward spaces.

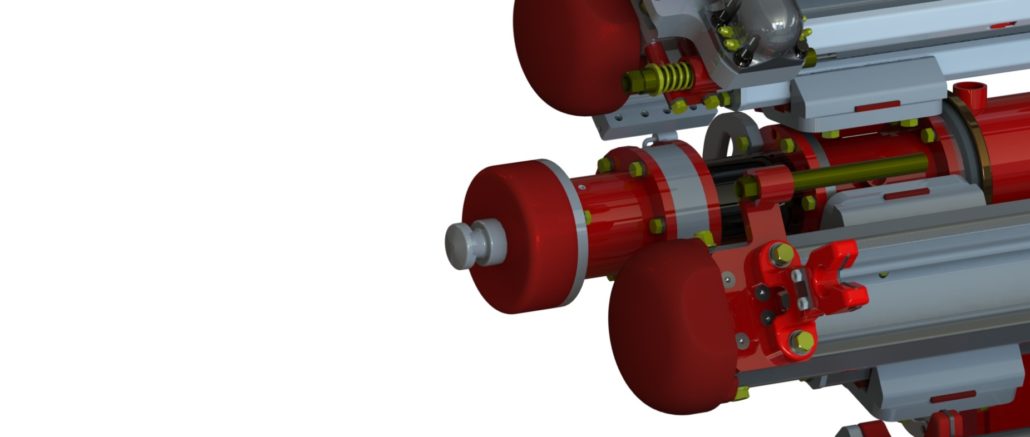

Bolt Carousel:

Bolters have an option of a bolt holding/ loading carousel assembly. The carousel holds all types of bolts: split-sets, swellex, rebar, rock bolts, etc. The bolt carousel is hydraulically operated from the unit, and increases bolting cycle efficiency.

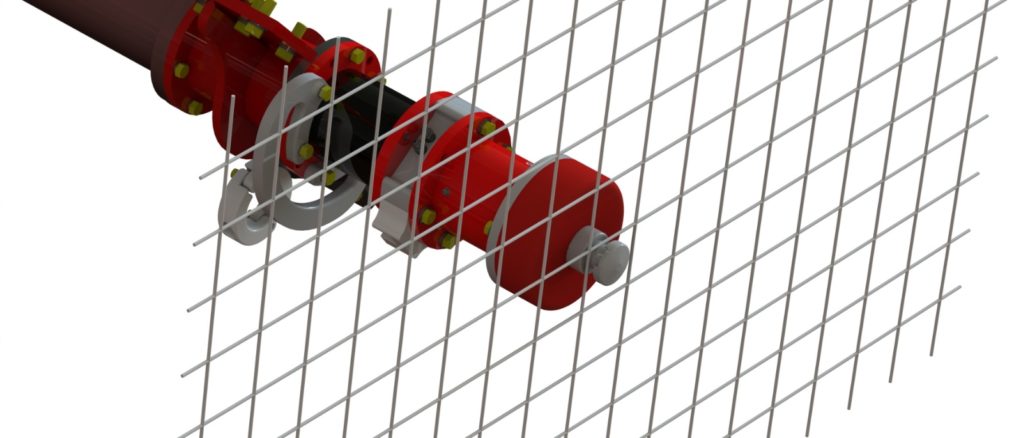

Patented Screen Handler:

Our patented screen handler design is mounted directly to the bolter stinger tube, making it convenient for operators to hang screen.